Protektive Pak Dissipative Impregnated Corrugated Material meets ANSI/ESD S20.20 and Packaging standard ANSI/ESD S541, tested per ANSI/ESD STM11.11 and

modified ANSI/ESD STM11.31

A common problem in the electronics industry is protecting static sensitive product when it is transported or stored outside an ESD Protected Area (EPA).

In addition, the movement of circuit boards or other assemblies containing electronic components within a facility or shipping from subcontractor sites

creates potential for ESD and physical damage. Protektive Pak’s Dissipative Impregnated Corrugated material offers protection from both.

"Packaging materials that are in intimate contact with devices should be dissipative" ANSI/ESD S541 section 7.2.2 Resistance of Dissipative Materials.

Independent Testing

PROVEN...

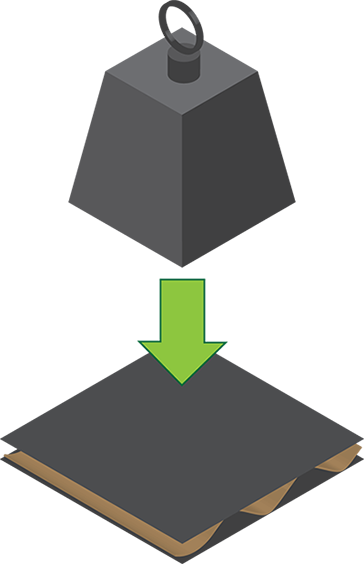

- Protektive Pak Impregnated Corrugated material has a buried shielding layer

- Protektive Pak Impregnated Corrugated material equals or exceeds the discharge shielding capabilites of a coated box

- Protektive Pak Impregnated Corrugated material has discharge shielding capabilities equal to a metal-out shielding bag

- Protektive Pak Dissipative Corrugated material meets the ANSI/ESD S541 recommendation, avoiding rapid discharge when contacting ESD sensitive items

- conductive coated boxes DO NOT!

Independent tests proves Protektive Pak Dissipative Impregnated Corrugated Material is superior to coated material.

Independent tests were conducted by Steve Fowler, Fowler Associates, Inc. and resulted in the conclusions above.

See Test Results

ESD Handbook ESD TR20.20 section 5.4.3.3.1 Returnable and Reusable Packaging, "In some situations, packaging may be designed for reuse [and] may be reused

numerous times. Examples of these types of ESD protective packaging are hinged containers, boxes, and other rigid or semi-rigid containers. The initial

cost of these packages may be relatively expensive. However, if the appropriate collection and recycling system is used, the container may be the least

expensive choice over time."

"ESD protective packaging shall be marked with the ESD Protective Symbol. "Packaging should be marked with information that allows traceability to the packaging

manufacturer and to the manufacturer's date/lot code information. The date/lot code should allow traceability to quality control information pertaining to the

manufacture of the specific lot of packaging."

(ANSI/ESD S541 section 8.2.1 Material Identification and section 8.2.3 Traceability)

"Packaging materials that are in intimate contact with devices should be dissipative" ANSI/ESD S541 section 7.2.2 Resistance of Dissipative Materials.

X

Receiving

X

Inspection

X

Auto Assembly

X

Shipping

X

Stockroom

X

Engineering

X

Assembly

Why Dissipative Impregnated Corrugated Material is the Best Choice for ESD Control Packaging

| |

IMPREGNATED MATERIAL |

COATED MATERIAL |

| 1 |

CONSISTENT QUALITY

Manufactured by one paper mill with computerized control, resulting in consistent high quality. |

Manufactured without computer controls and applied at various geographical locations, resulting in quality variations. |

| 2 |

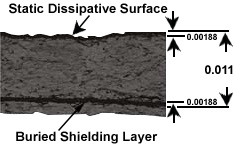

STATE-OF-THE-ART TECHNOLOGY

Carbon is added during the paper making process. The paper is a 6 layer process. The top surface layer is static dissipative, measuring

1 x 106 to <1 x 109 ohms. The conductive layer is in the 5th layer from the surface measuring < 1 x 104 ohms. |

Material is coated or printed with carbon loaded black ink which is then coated with a clear sealer to help coating stay on. Shielding layer is very

close to surface and high carbon content can bleed through. Result is poor and inconsistent static dissipative effectiveness. |

| 3 |

LOWER SULFUR CONTENT

Manufactured from 100% recycled paper with consistently low sulfur content. |

Manufactured from either recycled or virgin paper or a combination of both. Sulfur content may be low or high which can cause corrosion to leads and circuits.

|

| 4 |

GREATER DURABILITY

1,000 Times Thicker Abrasion tests have shown no loss in particles at 100 cycles, only 1% loss for 200 cycles and 60% loss for 500 cycles.

|

Tests have shown a 50% loss in particles in only 10 cycles and a 100% loss in 100 cycles.

|

| 5 |

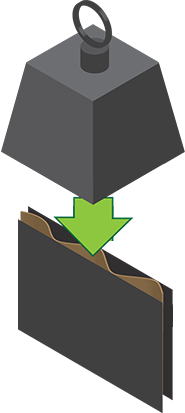

SLOWS RAPID DISCHARGE

Burying the conductive layer under a dissipative surface reduces the potential for a rapid discharge when contacted by a charged device.

|

A very conductive surface that may pose a charged device model (CDM) ESD danger to components stored in open bin boxes,

in-plant handlers, shippers, totes, nesting trays, etc.

|

| 6 |

BETTER SHIELDING EFFECTIVENESS

Shielding effectiveness is equal to or greater than coated conductive materials.

|

Some coated products shield poorly due to inconsistent application procedures by some manufacturers.

|

| 7 |

BETTER VALUE

More durable structure, 1,000 times thicker, which consistently shields your product from ESD, is also safer and better for the environment.

|

Simple structure which can lack consistency of ESD shielding, durability, and safety. |

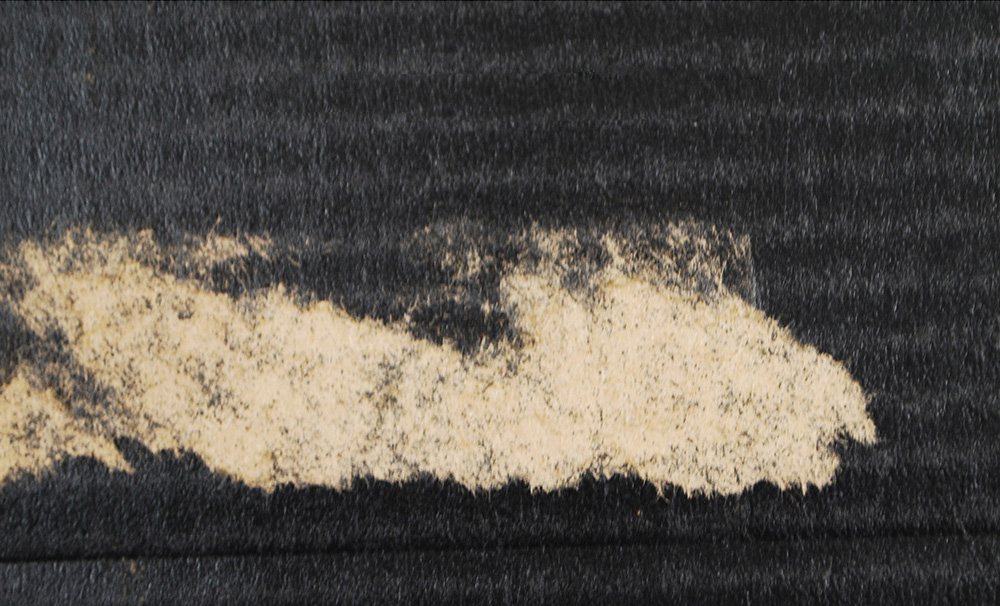

Dissipative Impregnated Corrugated Material

Dissipative Impregnated Corrugated Material

- Dissipative buried shielding layer mixed in during paper making process - does not rub or scratch off

- Does not lose its ESD properties

- Longer lasting ESD safe package

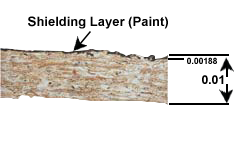

Coated Material

Coated Material

- Standard Kraft sheet with ESD properties painted or printed on surface

- ESD material is fragile and prone to scratch and rub off

- Not as long lasting

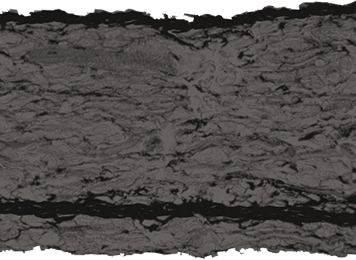

Cross Section of Dissipative Impregnated Corrugated Material and Coated Material

| |

|

Other Coated Material |

Other Coated Material |

| |

|

|

|

Microscopic cross section of

Protektive Pak's impregnated

corrugated linerboard |

Microscopic cross section of

carbon coated linerboard |

Microscopic cross section of

graphite printed linerboard |

| |

| All microscopic photos are approximately the same scale. |

|

| |

- Carbon added during the paper making process

- Paper is a 6 layer process

- The top surface layer is static dissipative (measures 1 x 106 < 1 x 109 ohms

- Conductive layer is the 5th layer from the surface (measures < 1 x 104 ohms)

- Abrasion test of its thicker construction has shown no loss in particles at 100 cycles, only 1% loss for 200 cycles and 60% loss for 500 cycles.

Similar tests performed on the coated material have shown a 50% loss in particles in only 10 cycles and a 100% loss in 100 cycles.

When dissipative impregnated corrugated container is enclosed (such as a lid in place), the buried shielding layer provides ESD shielding,

protecting contents from electrostatic charges and discharges.

Protektive Pak Impregnated Corrugated

Material Strength

There are two basic test methods to prove the physical strength of corrugated material

- Mullen Burst Test is the puncture resistance measurement for corrugated material

- ECT Test reveals the stacking strength or crushing resistance of corrugated material

Test Results

The industry standard for this material strength should yield:

- 200 for the Muller Test

- 42 for the ECT Test

Mullen Test (Burst Test)

Coated material: 216.8

Protektive Pak Impregnated Material: 284.4

ECT Test (Edge Crush Test)

Coated material: 41.3

Protektive Pak Impregnated Material: 53.3

Summary

The Protektive Pak material had 29% better stacking strength/crushing resistance and 31% better puncture resistance than the coated material.

Protektive Pak’s Impregnated Corrugated Material is physically stronger!

Protektive Pak’s statements are backed by technical data based on independent tests. Independent Testing available upon request.

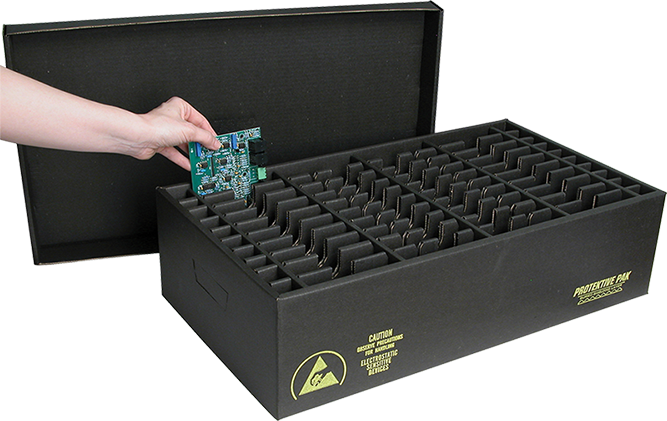

Returnable Packaging

In-Plant Handlers

Constructed with double thick sides and double or triple thick ends, Impregnated Corrugated containers are built to withstand the abuse

of transportation and continuous reuse, making them a great choice for returnable packaging.

Potentially the least expensive packaging choice over time. Also, because the shielding layer is built into the corrugated material, the boxes will

maintain a quality appearance much longer than painted or coated product.

After transporting product to another facility, the boxes can be reused to ship more product or collapsed and stored for future use.

REDUCE COSTS

REDUCE COSTS

|

REDUCE WASTE

REDUCE WASTE

|

| Returnable packaging is much less expensive in the long term |

Eliminate repeated purchases |

ESD Handbook ESD TR20.20 section 5.4.3.3.1 Returnable and Reusable Packaging, "In some situations, packaging may be designed for reuse [and] may be reused

numerous times. Examples of these types of ESD protective packaging are hinged containers, boxes, and other rigid or semi-rigid containers. The initial cost

of these packages may be relatively expensive. However, if the appropriate collection and recycling system is used, the container may be the least expensive

choice over time."

ESD Marking and Traceability

"ESD protective packaging shall be marked with the ESD Protective Symbol. "Packaging should be marked with information that allows traceability to the

packaging manufacturer and to the manufacturer's date/lot code information. The date/lot code should allow traceability to quality control information

pertaining to the manufacture of the specific lot of packaging."

(ANSI/ESD S541 section 8.2.1 Material Identification and section 8.2.3 Traceability)